Technology / Certifications

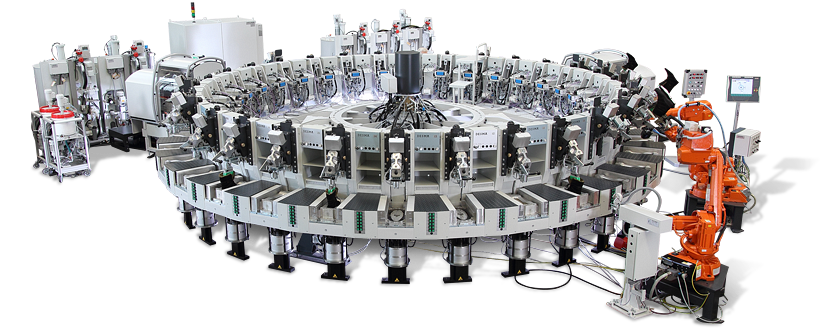

DESMA has been one of the market leader in Shoe machinery and Moulds, especially due to the advanced PU-PVC technologies. Direct soling machines are offered for single- or dual-density applications

BMJ Safety Shoes are manufactured using DESMA German State-Of-Art Technology and Machinery, spanning the last 70 years. Its stringent processes meeting with ISO 20345:2004, ISO 9001:2008 and Singapore’s PSB standards.

Critical Testing Requirements

| TEST | SS 513: 2005 Requirements | |

| Flexing of Steel Mid-Sole | Must show no visible signs of cracking |

| Upper/Outsole Bond Strength | 4.0 min., if tearing 3.0 min |

| Anti-Static | Dry: >= 100KΩ Wet: >=1000MΩ |

| Impact Test | Toe cap is subjected to an impact energy of 200 Joules falling freely. Min 15 mm |

| Nail Penetration Test | A) Construction: Shall be built into the bottom of the shoe in such a manner that it cannot be removed without damaging the footwear. B) Fastening – Not more than 3 hole each of max. diameters of 3mm D) Penetration resistant – 1100N Min. |

Certifications

| SINGAPORE STANDARD SS 513 : Part 2 : 2005  | The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 388:1994, Protective gloves against mechanical risks |

| CE” originated as an abbreviation of Conformité Européenne, meaning European Conformity. CE marking is a mandatory legal conformity requirement for all products sold within the European Union that fall within the scope of a directive which requires a CE marking. By affixing a CE marking to a product and signing the Declaration of Conformity, a product supplier is declaring to the EU authorities that the minimum requirements of all applicable directives have been met. Depending on the directive, involvement of a European Union ‘Notified Body’ may be mandatory for certain types of products |

| “ISO 9001 Certified” means an organization has met the requirements in ISO9001. It defines an ISO 9000 Quality Management System (QMS). ISO 9001:2008 is focused on meeting customer expectations and delivering customer satisfaction so you must pay attention to the customer. |